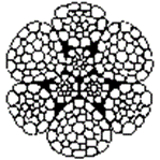

Flex-X 9 features compacted strands and swagging for extra drum crushing resistance and increased stability. Its high density strands deliver extra strength and resistance to abrasion. Flex-X 9 is manufactured with a dual compaction process to produce a compact cross-section with minimum voids and greater surface area on outer wires that contact drums, sheaves and the rope during operation. The high-density compacted strands minimize nicking at strand-to-strand contact points.

Flex-X 9 was specifically designed for boom hoist applications where drum crushing is a challenge. Flex-X designs reduce drum scrubbing between the lead line and the previous wrap. The smooth contact creates less interference, less metal loss and wire deformation. The increased surface area of Flex-X can be seen in the comparison of the contact points of a standard 6x26WS and Flex-X as shown.