High Performance Hoist Rope

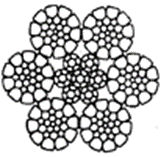

Flex-X 6 users receive superior performance and increased service life in many applications compared to the ropes they had previously employed. When compared to conventional six strand ropes, Flex-X 6 ropes provide greater surface area and more steel per given diameter. This increases rope stability and strength. This results in a longer service life and less sheave and drum wear.

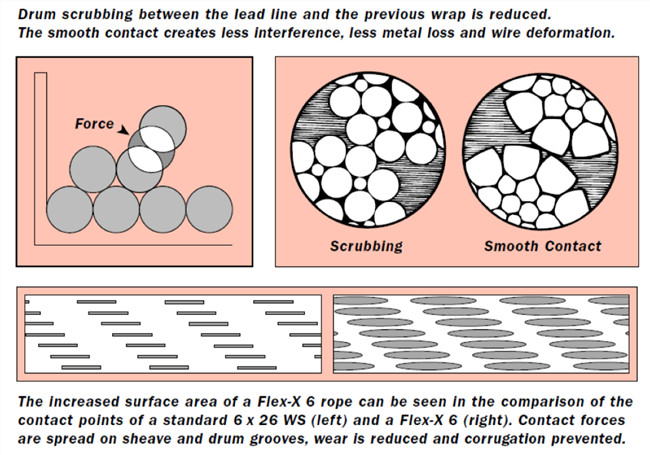

Flex-X designs reduce drum scrubbing between the lead line and the previous wrap. The smooth contact creates less interference, less metal loss and wire deformation. The increased surface area of Flex-X can be seen in the comparison of the contact points of a standard 6x26WS and Flex-X as shown.

Most applications for wire rope are extremely demanding. Wire rope must resist crushing, bending fatigue and abrasion. For example, clamshell closing lines must resist bending fatigue and boom hoists are subject to pressures that cause crushing. Overhead hoists test the stability and strength of a wire rope. All drum-related applications demand a rope that will spool and operate smoothly and dependably. If you recognize these conditions, then Flex-X 6 is for you. Flex-X 6 users receive superior performance and increased service life in many applications compared to the ropes they previously employed. When compared to conventional 6 strand ropes, Flex-X 6 provides greater surface area and more steel per given diameter, which increases stability and strength. This results in longer service life and less sheave and drum wear. It also lowers your cost of operation.